Creating the perfect golf bag with Formlabs 3D printing

Earning a space in a player’s golf bag is a great honor. That’s what TaylorMade has been doing for over 30 years, delivering on its promise to create the best performing golf products in the world. Whether they are intended for beginners looking to improve their putt, or for PGA Tour pros who want an added edge. The result? The most prestigious golf clubs in the industry.

“Tiger Woods' expectations are very high: he is the most demanding golfer ever. He inspects every inch of the stick. For TaylorMade it is a great satisfaction to have earned a place in his bag. "

– Chris Rollins, TaylorMade Product Development Engineer

40 years of innovation

It all started with a single club. In 1979, TaylorMade’s Pittsburgh Persimmon Metal Headed Wood Club radically changed modern golf. The first metal-headed driver to be adopted by a large number of golfers was a dramatic improvement over the wood-headed ones of the time, as it allowed players to get the ball farther. For TaylorMade, this product was the launch pad, but to get to the top it took a real and continuous dedication to innovation and improving player performance. Forty years later, when a player walks into a store and sees the TaylorMade logo on a golf club, he knows that the vision and love of the game that characterized that first club continues to be an integral part of every new design. .

Speed and uniformity

Sim Fairway represents the best of TaylorMade. Redefining the limits of golf club design, Sim Fairway represents a continuous improvement in terms of ball speed, throw height, and, most importantly, greater consistency for players.

Designing a new club begins with brainstorming. The team reflects on the different innovations they think they can make and the problems they will solve. In the case of the creation of SIM Fairway, the company aimed to find new ways to lower the center of gravity, improve the interaction with the turf and the flexibility of the surface. The engineers got to work creating a new head from scratch, starting with two-dimensional designs and performance analysis. The goal was to redesign the way weights are placed inside the clubhead, improving performance with each swing.

Without having to worry about prototyping costs, the team turned on the in-house 3D printers to bring the CAD files to life. Working on three-dimensional models is critical to TaylorMade, as it allows you to physically see and test how different designs and weight distributions affect the clubhead. The radical new look of SIM Fairway is a direct result of this process. The resulting product has a stunning new look and new benchmark performance for gamers.

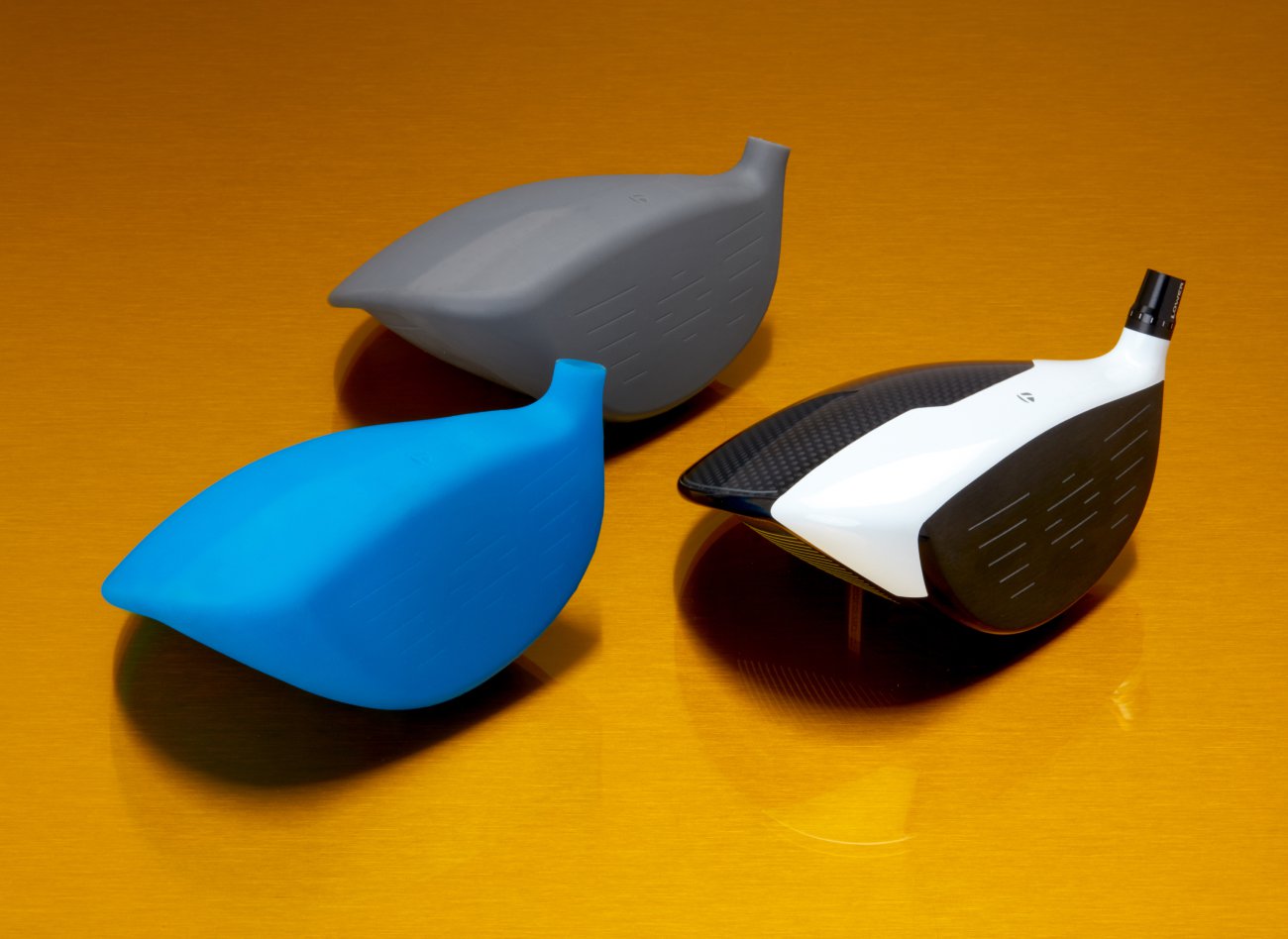

Draft Resin and Gray Resin to create performance golf clubs

The team uses Draft Resin to quickly print new parts in a few hours and then switches to Gray Resin for prototypes oriented to the final appearance of the product. Top-line masking of prototype heads made from Gray Resin was a big plus for designers, thanks to the high-quality plastics available for Formlabs 3D printers.

The ability to create perfectly complementary parts is another feature that distinguishes Gray Resin from the alternatives that engineers have considered when choosing in-house printers. The creation of complementary 3D printed parts allowed the team to test numerous new shapes for inserting weights into the bottom of the SIM Fairway, thus creating a better club. For TaylorMade engineers, the print materials were the key element in their quest to create a better fairway wood.

The next 18 holes

TaylorMade has a specific goal: to create the best set of golf clubs in the world to make you a better golfer. This means making clubs that can improve regularity, facilitate the correction of imperfect shots and increase the swing speed. TaylorMade has created a team of world-class engineers and designers, who have the same passion for golf as the pros who use their products, and has given them the ability to create affordable in-house 3D prints, proving to the world of golf. golf that there is no limit to innovation.

When a player takes a TaylorMade club out of his bag, he is confident that the next eighteen holes will be the best ever.