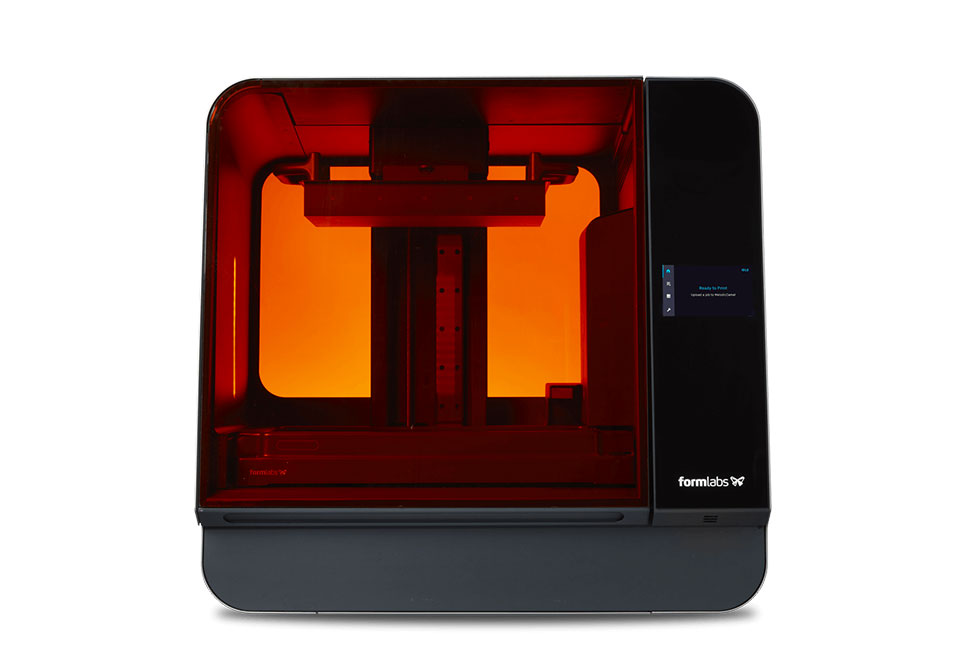

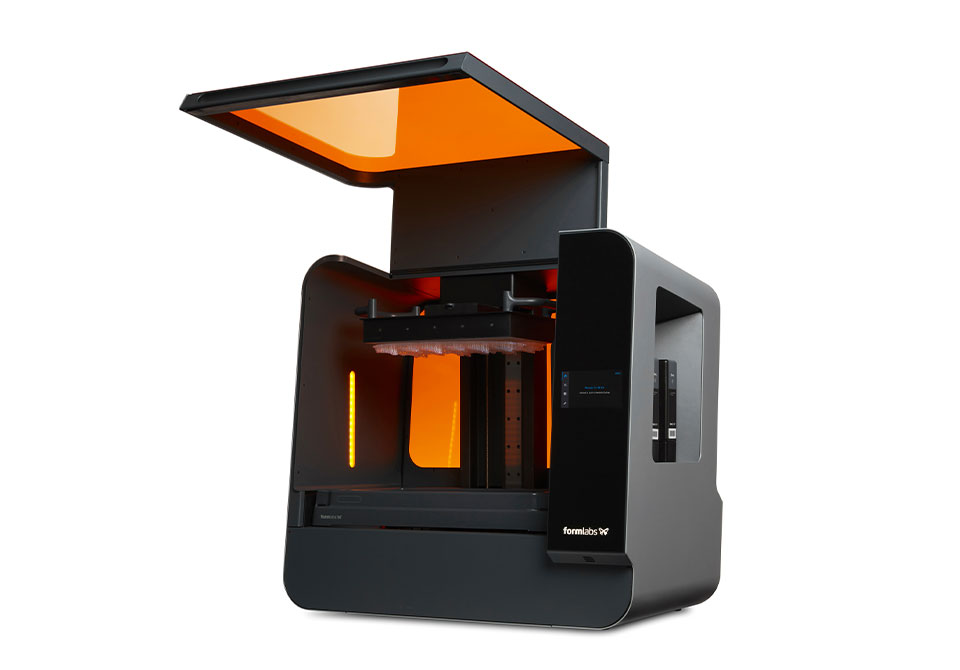

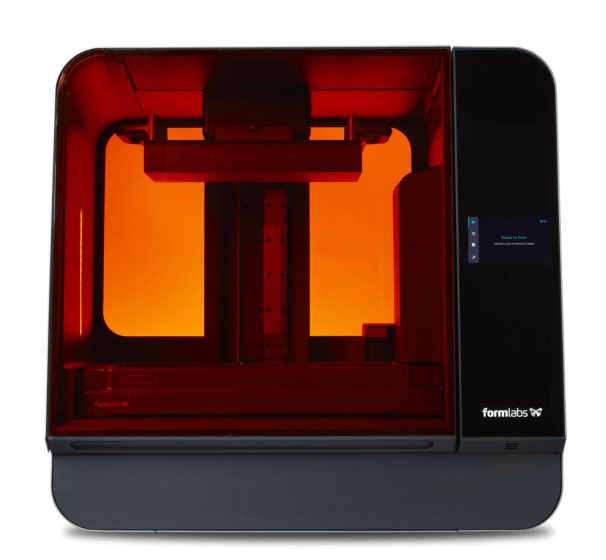

Form 3BL

Stampante 3D a grande formato avanzata ottimizzata per i materiali biocompatibili e le applicazioni dentali e mediche.

Form 3BL is the 3D printer that takes additive manufacturing for the dental industry to the next level: it is a machine designed for high volume production. A new generation 3D printing ecosystem specifically designed to meet the needs of dental professionals. Reliable and accurate, it eliminates the uncertainties associated with dental production, so that positive clinical results can be achieved in just a few clicks. Form 3BL is designed for the dental market both for the exclusive use of specific biocompatible resins and unique software features.

Learn more about Form 3BL