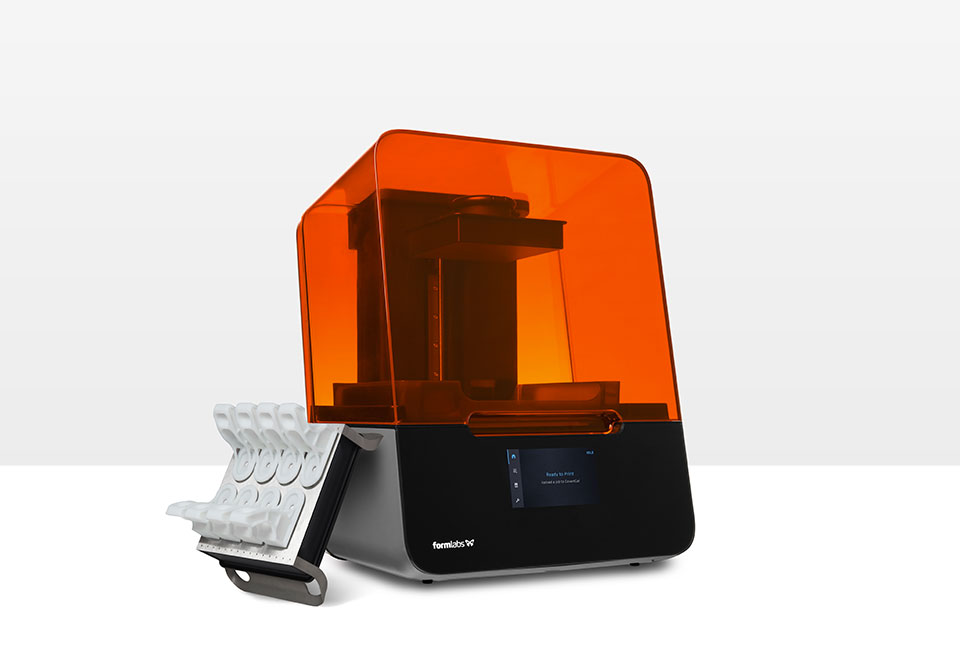

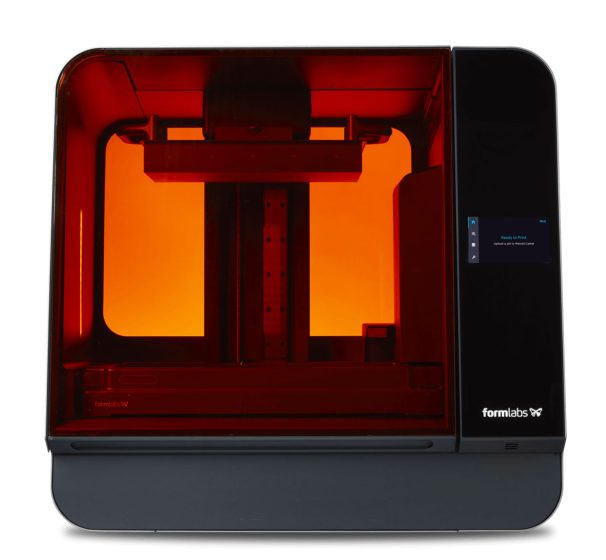

Form 3+

The desktop resin printer with the best value for money

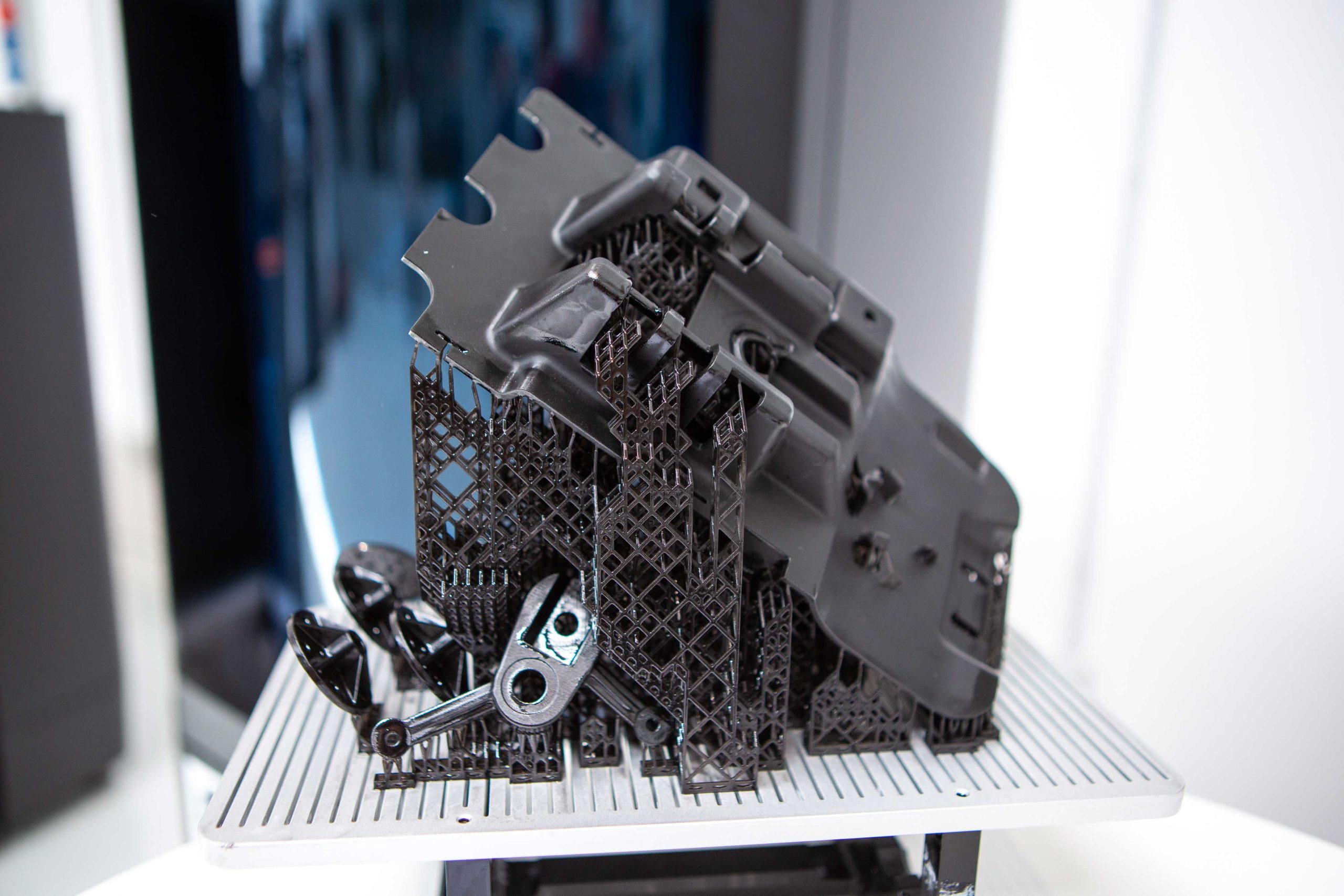

The industrial quality printer for quick and easy production of reliable, high quality prototypes and final parts. With Form 3+, you can easily grow your prototypes and production as your business grows. With advanced LFS™ technology and a precise, uniform 85 μm laser dot across the entire print area, Form 3+ is capable of reproducing the smallest details with the greatest accuracy.

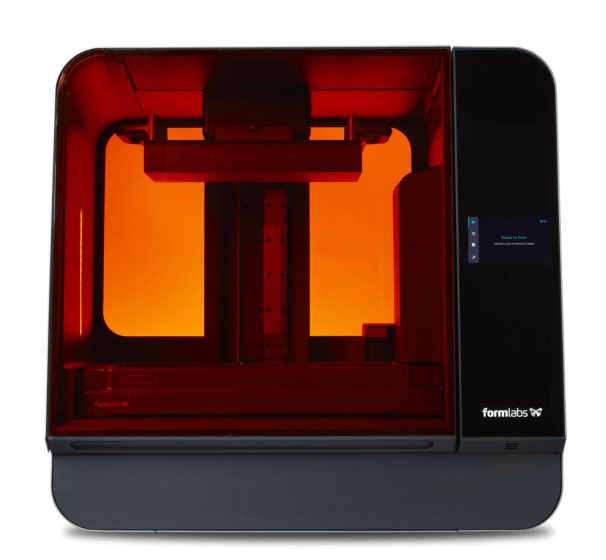

- Print volume

- 14.5 × 14.5 × 18.5cm

- layer thickness

- 25 – 300μm

- laser power

- 250mW

- XY Resolution

- 25μm

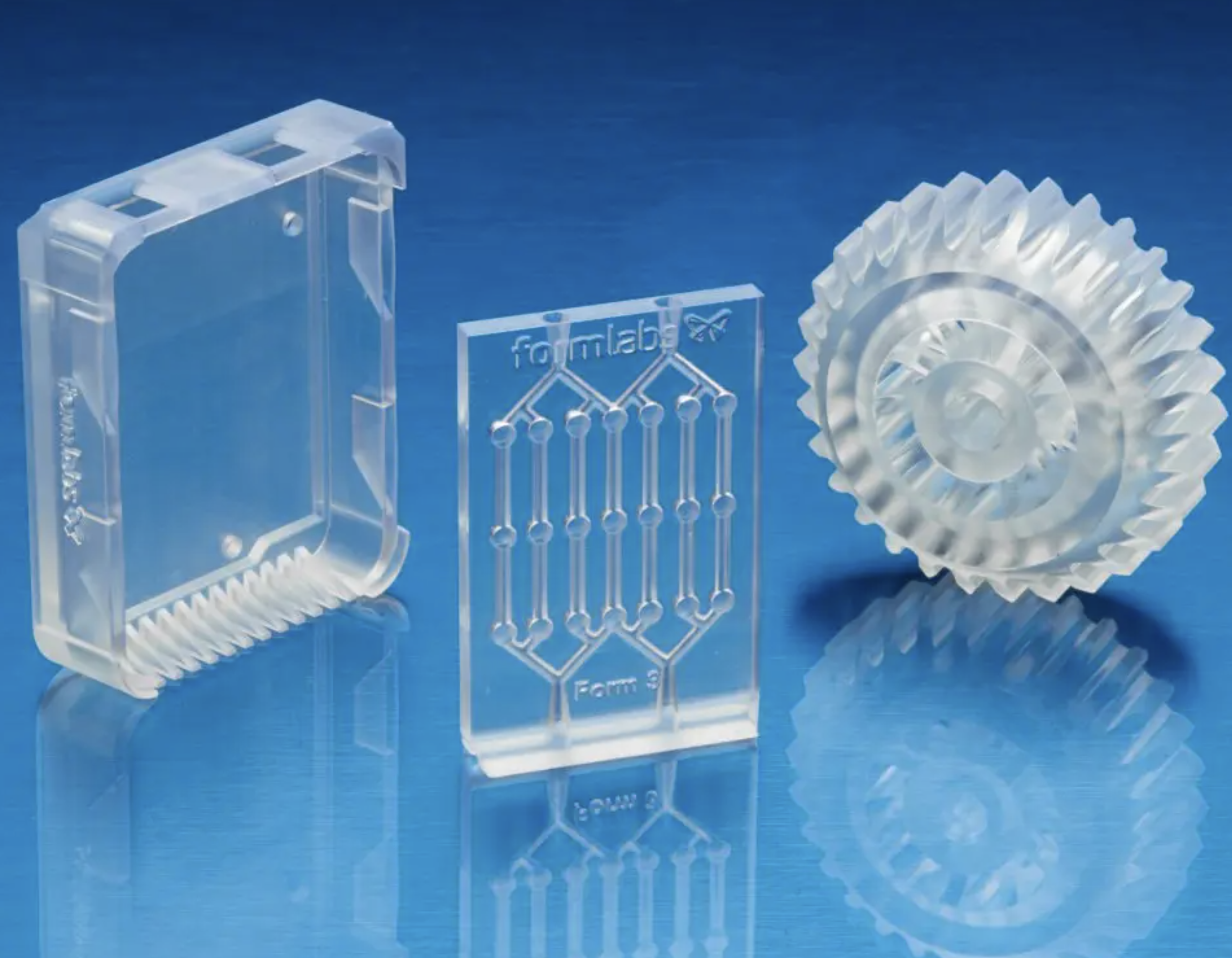

Greyscale Resins

Clear Resin

Draft Resin

Color Kit

Grey Pro Resin

Rigid Resin

High Temp Resin

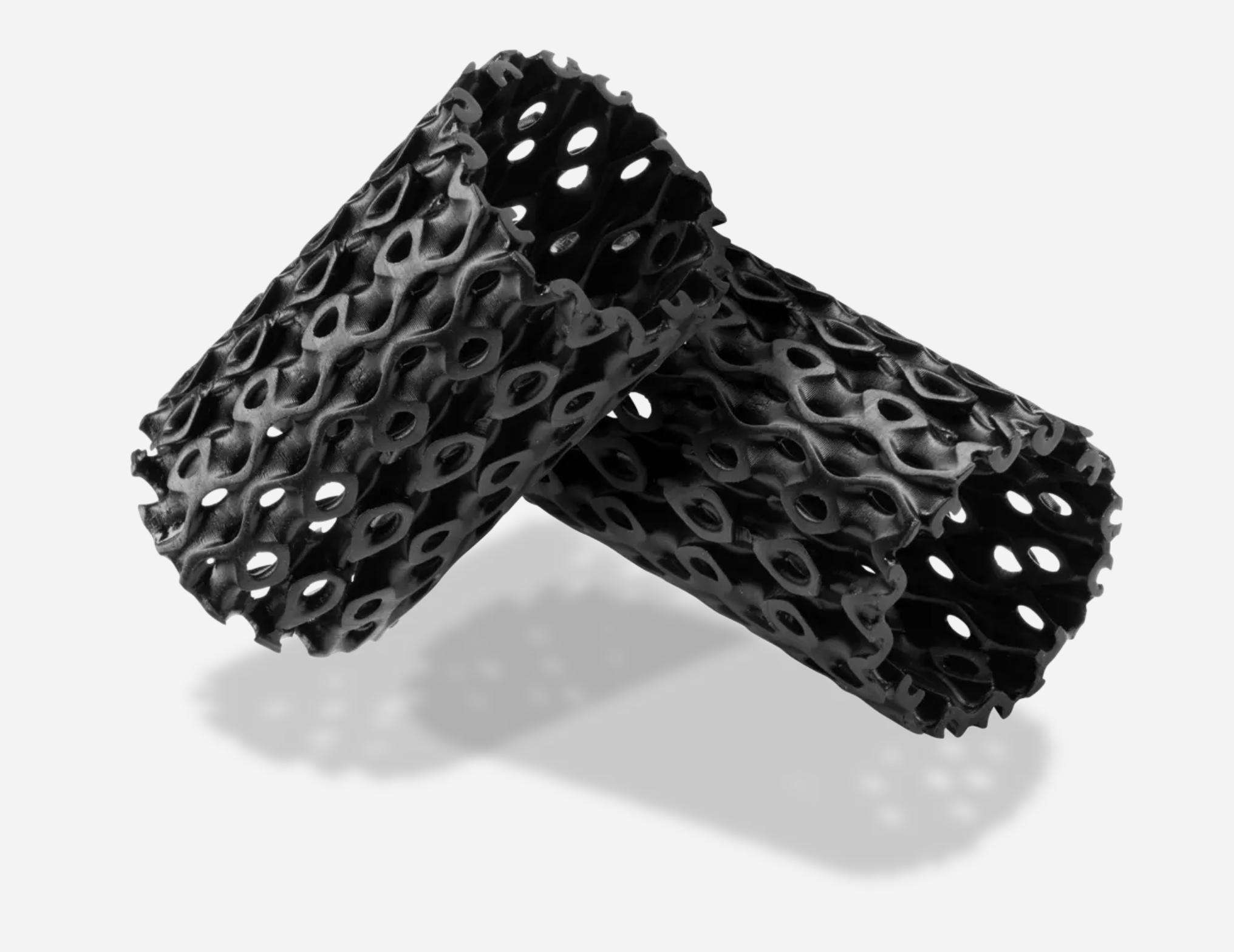

Flexible 80A

Elastic 50A

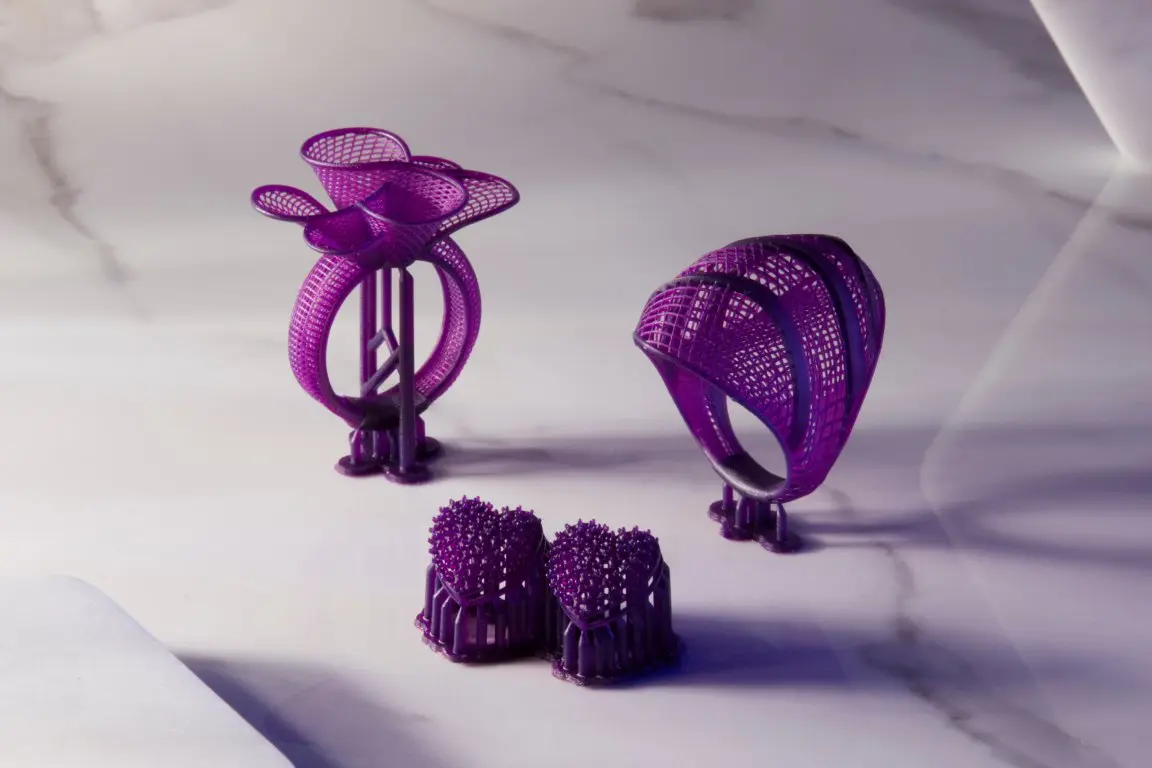

Castable Wax Resin

Ceramic Resin

Rebound Resin

Castable Wax 40 Resin

ESD Resin

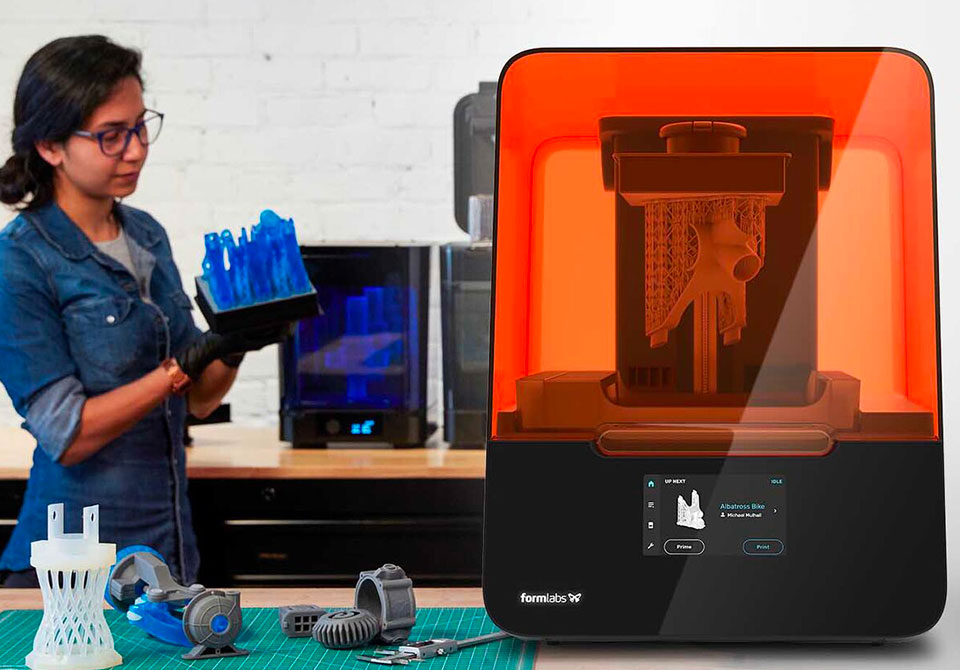

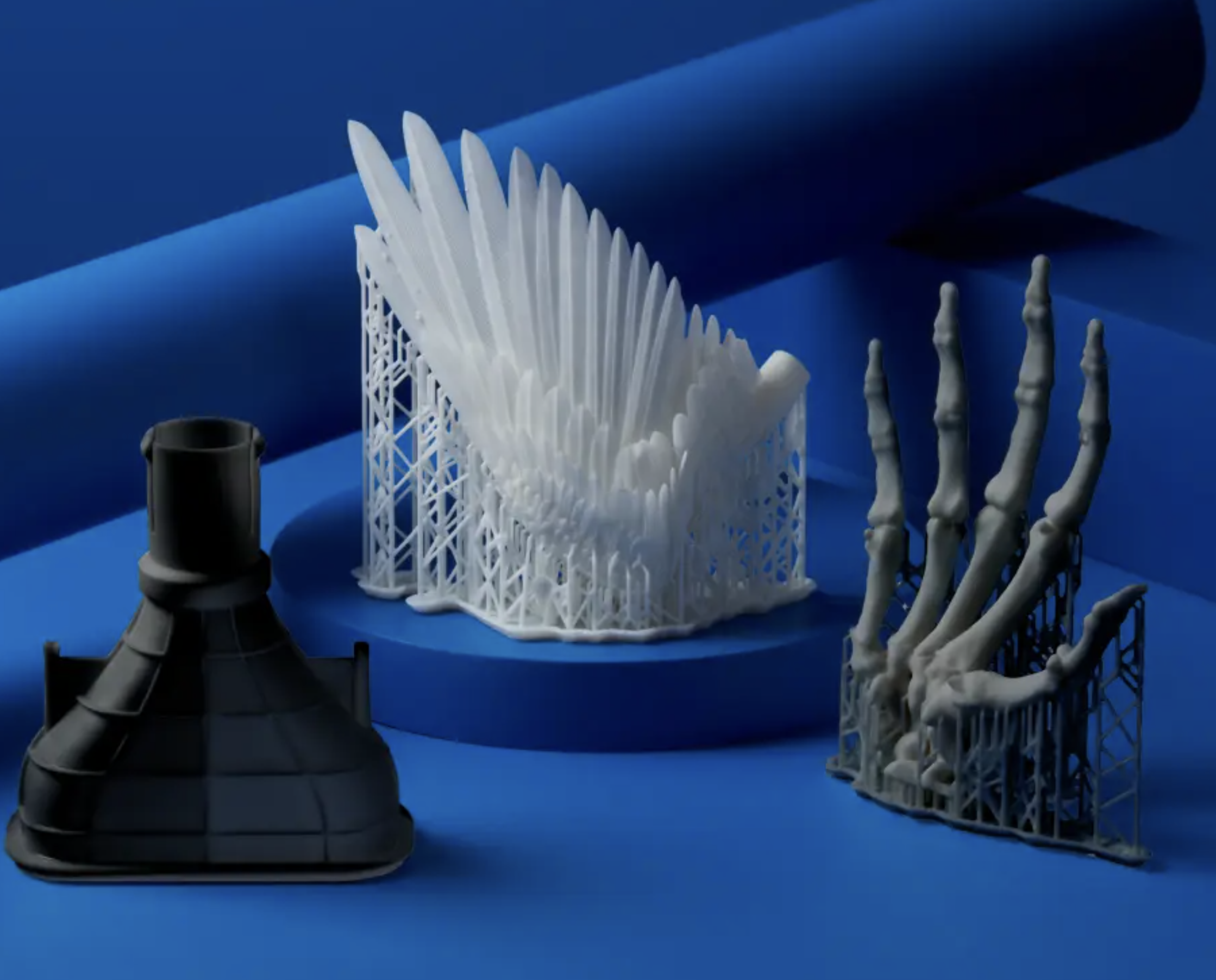

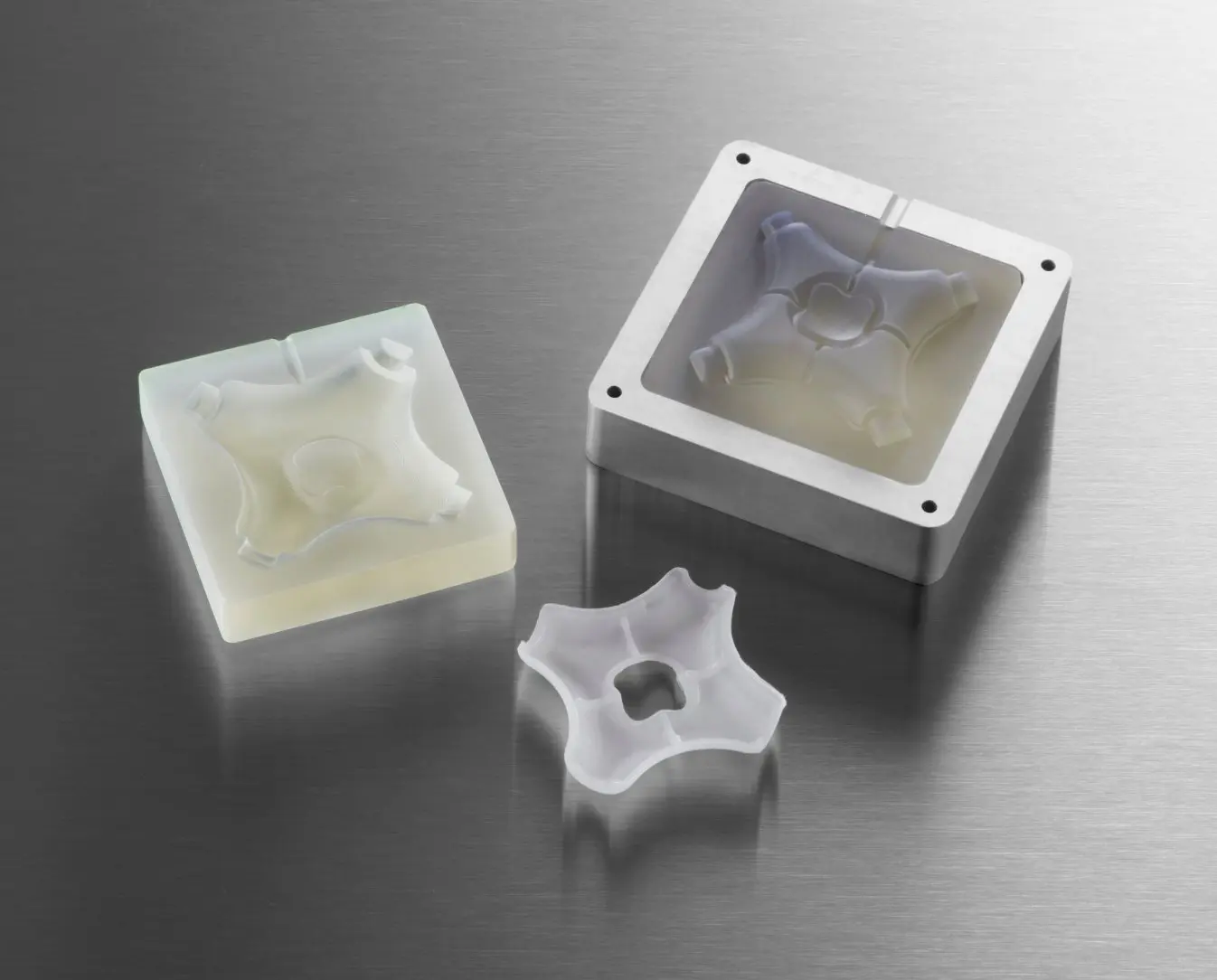

Prototyping

Verify and optimise your design for a perfect product in every respect. 3D printing makes it possible to produce high-quality prototypes extremely quickly, easily and inexpensively, which are essential for experimenting with alternatives or verifying every functional, aesthetic and design aspect, avoiding delays and errors.

Wash & Cure

For a perfect finish every time

Produce excellent parts with a tested and proven dental 3D printing workflow from start to finish and certified biocompatible. All 3D prints made by stereolithography must be washed and polymerised post-print to remove any uncured resin residue and achieve optimal quality. Our automated solutions simplify the post-processing process.

Automated and precise washing

Form Wash agitates isopropyl alcohol to perfectly clean the parts, then lifts them to allow them to dry once the wash is complete. Simply set the desired time and let Form Wash do the work. Once the washing is complete, the parts air dry and are ready for use.

Post-press polymerisation has never been easier

Our automated post-print curing solution, Form Cure, includes customised settings to maximise material performance, achieve consistent dimensional accuracy and meet biocompatibility requirements for each Formlabs resin at the touch of a button.

Preform

Optimise Printing Processes in PreForm

Design your model in standard CAD software and import it into our PreForm print preparation software in STL or OBJ format. Prepare your model in minutes, upload it to the printer and start printing.

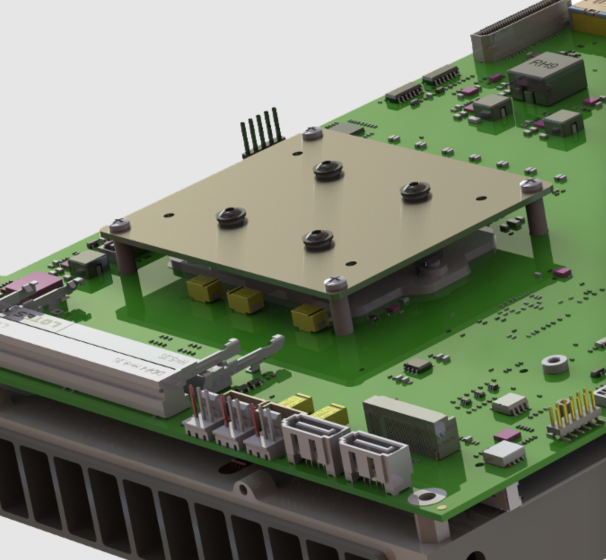

A faster printing process

The Light Processing Unit (LPU) evenly distributes the light over the entire area, enabling the same part quality to be achieved across the entire printing plate.

Reduced printing times

The high intensity laser and optimised settings for specific materials enable shorter print times.

Download

Contact us to get more information and request a quote