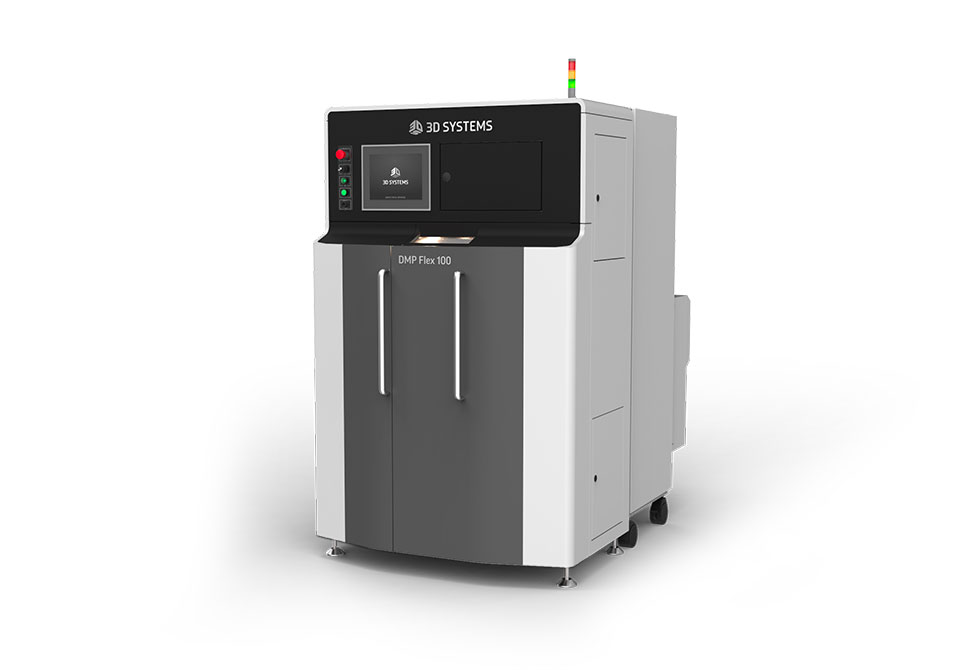

DMP Dental 100

La miglior stampante 3D a polvere di metallo per il settore dentale

DMP Flex 100 dental, creates small, dense and complex dental prostheses with excellent surface quality and short post-processing with high productivity. Thanks to its increased power, this 3D dental printer achieves up to twice the productivity of the previous 3Dsystems printer, resulting in lower part costs and shorter production times. Print more than 90 crowns in less than 4 hours, in a single run. The DMP Dental 100 works with a roller and very small dust particles, which reduces post-processing times to a minimum. For example, for 90 crowns, stress relief takes no more than 25 minutes.

Learn more about DMP Dental 100